Industrial

State of the art technology offered by a global team of experts

Applications

- Media Retention

- Screening

- Dewatering

- Collection

- Distribution

- Separation

- Product recovery

Advantages

The all welded construction offers unmatched benefits

- Maximum open area

- Flexibility in design

- Smooth Working surface

- Non - clogging openings

- Optimised collection and distribution

- Increased wear life

- Low pressure drop

- High Mechanical strength

- Ease of Cleaning

Industry

Segments

- Chemical Plants

- Food Processing

- Paper & Pulp

- Sugar Mills

- Starch Processing

- Salt Plants

- Water Treatment Plants

- Waste Water Treatment and various process Industries

Header Laterals, Resin Traps. Nozzles, Candle Filters

Flexibility in Design

- Each screen is designed and manufactured to ensure complete customer satisfaction

- Screens can be designed and manufactured to suit individual applications. E.g. Circular, reverse screens, screen baskets, pipe base, curved screens or sieve bends and many more.

- Cylindrical screen apertures ≥ 80 micron are available for fine screening or media retention, in diameters as small as 40 mm (1.5")

- Reverse screen apertures as fine as 100 micron and diameters of 200 mm (8") can be supplied to suit customer requirements.

- Flat screens or support grids can be supplied with apertures starting with 80 microns.

- All our wedge wire screens can be supplied in standard material of SS304/ SS316/ SS316L. Many other material grades are available on request.

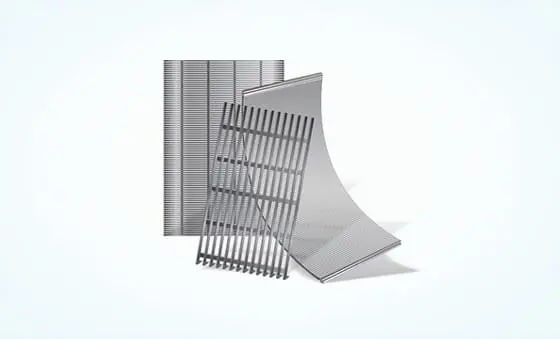

Flat Screen & Seive Bend

Oil Mill, Sugar, Corn Processing, Food Processing; Flow in any direction based on application

Reverse Screen / Reverse Screen Basket

Salt, Paper, Sugar. Paint, Screw Press Waste Water; Flow in to out

© Copyright 2016, Apollo Screens