WATER WELL SCREENS

State of the art technology

offered by a global team of experts

An extensive range of high open are wire wrap screens for ground water applications.

Advantages

- Increased water flow

- Reduced energy consumption

- Effective and uniform well development

- Improved sand control

- Reduced pump maintenance

- Longer well life

Apollo Screens

for Water well &

sub surface water

applications

Apollo Screens; a company established in 2011 by the APOLLO GROUP, a renowned engineering house combining its engineering expertise with long term vision, ethical business approach and a global team of experts in design and manufacture of wedge wire screens for a wide range of applications.

Apollo Screen manufacturing facility:The plant & critical equipment for Apollo screens has been designed and built by the Apollo group's designers and engineers. The plant is equipped with state of the art screen fabrication technology to produce finest quality wedge wire screens with accuracy of wire drawing facility to achieve the highest product quality.

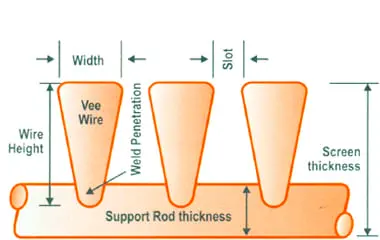

Designs of welded wire wrap

The all welded wedge wire screens are made from two elements -the V-shaped wedge wire is helically wound around an array of internal longitudinal support rods. Each intersection of wire and rods is automatically resistance welded, creating a very strong cage-like cylinder with one continuous slot spiralling along its full length. The gap between the wires, also called slot or aperture, is manufactured tocustomer specification, allows water to flow from the surrounding aquifer into the screen, The slots can be very narrow to keep out fine sand grains, which could otherwise damage your pump through abrasion.

Key design features of water well screen

Non Plugging slots

- V-shaped wire creating, two point particle contact preventing plugging.

- Inwardly opening slots (in-flow) preventing sand particlesfrom remaining lodged in screen.

- The V shaped wire enhances well efficiency, ensures consistent pumping and long well life.

Non Plugging slots

- The continuous slot wedge wire offers higher open area than any other type of screens use for water well applications, such as slotted pipe, punched pipe, louver screens.

- Wedge wires for each application are selected to maximize open area, resulting in the lowest possible cost for water extraction.

Technical details

- Availab le sizes from 1" (25 mm) to 22" (560 mm)

- Water well screens designed to suit well depth

- Available in slots sizes from 0.15 mm to 3 mm

- Lengths up to 7 metres available

- Materials: LCG (Low Carbon Galvanised) / SS304 / S316L / SS316 / SS316L - or as required to meet Customer requirements.

- End fittings - to suit Customer requirements