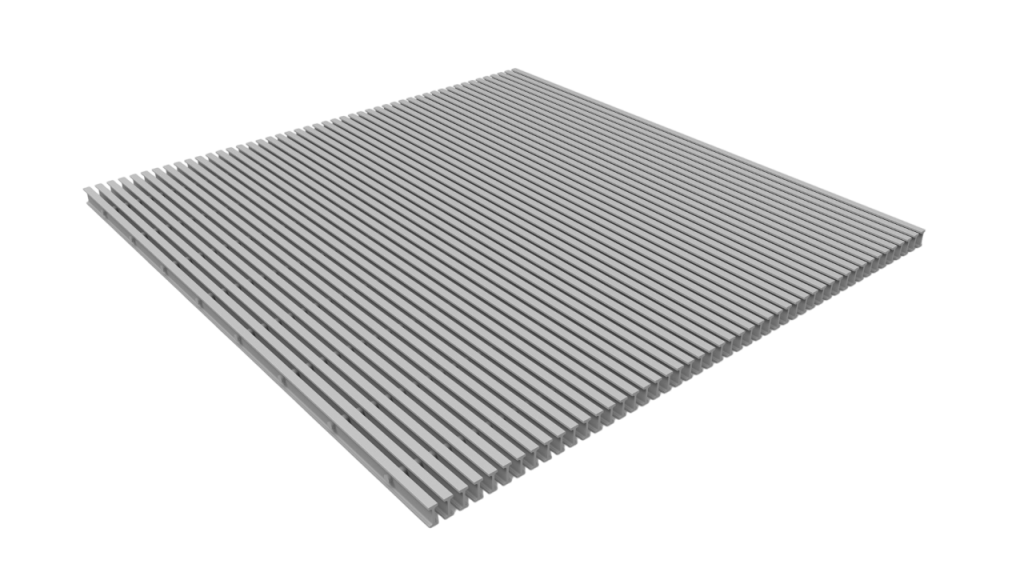

Wedge wire screens are manufactured using a robust framework where wedge-shaped wires are precisely wound and welded at defined intervals, creating consistent slot openings. This design allows effective retention of solid particles while enabling uninterrupted and efficient fluid flow. Due to these advantages, wedge wire screens are extensively applied in industries such as petroleum, chemical processing, and water treatment.

With capabilities including high-accuracy filtration, strong resistance to corrosion, anti-clogging performance, superior mechanical strength, and a long operational lifespan, wedge wire screens are essential for sand control applications in oil wells. They help improve output efficiency, protect downhole equipment, and play a key role in ensuring reliable and stable oil well performance.

Apollo Wedge Wire Screens, made from high-grade stainless steel, ensure non-clogging, hygienic filtration, safeguarding integrity and enabling safe production worldwide operations.

Food & Beverage Explore More

Durable wedge wire screens for efficient separation, dewatering, and processing in demanding mining operations, reducing downtime and enhancing productivity

Mining & Mineral Processing Explore More

Specialized screening systems for pulp cleaning, fiber recovery, and wastewater treatment, ensuring efficient production with reduced energy and resource consumption.

Pulp & Paper Explore More

Robust screening solutions withstand extreme conditions in oilfields, refineries, and chemical plants, ensuring reliable operations and safety compliance in critical processes.

Oil, Gas & Petrochemical Explore More

High-performance screens support cooling systems, fuel filtration, and renewable energy projects, delivering efficiency, durability, and reliability in energy generation processes.

Power & Energy Explore More

Versatile wedge wire screens enable solid-liquid separation, product recovery, and pre-filtration across global industries, reducing downtime and improving operational reliability.

Industrial Applications Explore More

Specialized wedge wire screens protect aquatic life, efficiently manage water flow, and support sustainable fish farming practices with durable, long-lasting reliable filtration solutions

Aquaculture & Fisheries Explore More

Innovative screening products enhance modern infrastructure, providing structural support, design flexibility, and durability for engineering and construction applications worldwide.

Architecture & Engineering (AEC) Explore MoreIf you need to consult the price, please contact the business department by E-mail:

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

Error: Contact form not found.

Reliable wedge wire screening solutions for water, wastewater treatment, and groundwater management — ensuring efficient filtration, sustainable clean resources, and long-term ecosystem safety worldwide.

Water, Wastewater & Environmental Explore More