Apollo Screens: Precision Wedge Wire Innovations, Water and Wastewater & Multidisciplinary Industrial Solutions

Initiated in 2014 by the Gujarat Apollo Group, a trailblazer in road construction equipment with a storied heritage spanning over five decades, Apollo Screens harnesses the group’s engineering prowess and global alliances to deliver exceptional wedge wire screens. Renowned for its pioneering technology and principled business ethos, Apollo Screens caters to a broad spectrum of industrial applications, specializing in solid-liquid separation, with a focus on excellence and dependability.

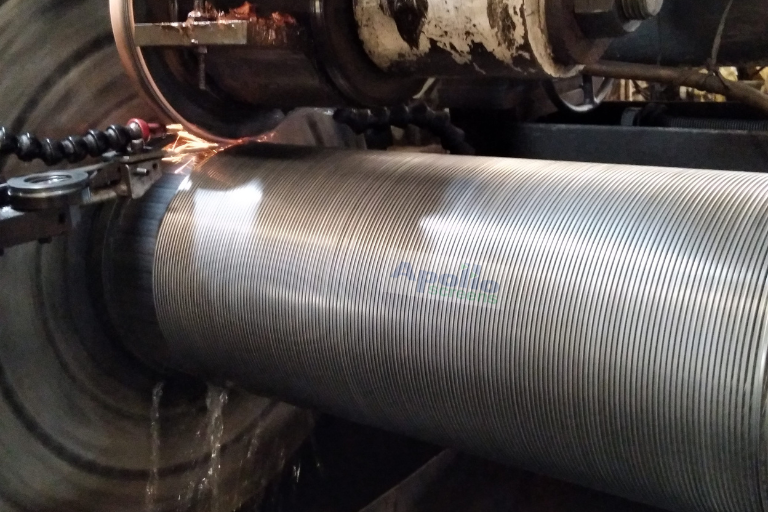

Cutting-Edge Manufacturing Hub

Nestled in Chhatral, near Ahmedabad, Apollo Screens Pvt. Ltd. boasts a sophisticated manufacturing facility crafted by the Apollo Group’s expert engineers. The plant is equipped with bespoke screen fabrication automats designed in-house and a specialized wire mill featuring V-shaped wire technology sourced from the USA. Certified with ISO 9001:2015 & ISO 14001:2015 accreditation, the facility produces meticulously engineered, all-welded wedge wire screens that adhere to stringent international quality benchmarks for solid-liquid separation and other applications.

Products and Applications

Apollo’s all-welded wedge wire screens are engineered for superior solid-liquid separation, solid/solid, and gas separation processes, serving diverse industries, including:

• Water Well Screens: For potable water wells and rainwater harvesting systems.

• Sub-Surface Water Extraction: Enabling efficient groundwater extraction.

• Oil & Gas Well Screens: For effective sand control in energy applications.

• Mining Screens: For mineral processing and solid-liquid separation.

• Wastewater and Raw Water Treatment: Screens for solids removal in water and wastewater treatment processes.

• Specialized Solutions:

– Apollo Roof Top Filter

– Water Intake Screens for rivers, lakes, canals, dams, and ponds

– Underdrain Systems for rapid sand filter beds in water treatment plants (WTP)

– Multi-Rack Bar Screens and Fine Screens for sewerage pumping stations and treatment facilities

Expert Leadership and Team

Apollo Screens is powered by a cadre of seasoned professionals with deep expertise:

• Marketing & Product Support: Spearheaded by a veteran with over 19 years of experience in water process applications, including solid-liquid separation, having successfully executed numerous projects across India.

• Manufacturing: Directed by an expert with 15 years of specialization in analogous product lines.

• Design: Guided by a professional with 15 years of expertise in wedge wire screen innovation for solid-liquid separation and other applications.

• Quality Control: Overseen by a specialist with 15 years of experience ensuring unparalleled product standards.

Commitment to Distinction

Rooted in the Gujarat Apollo Group’s illustrious tradition and fortified by global technological partnerships, Apollo Screens delivers bespoke, high-performance solutions for water, wastewater, and industrial solid-liquid separation applications. Our steadfast dedication to innovation, quality, and client satisfaction ensures robust, reliable products tailored to meet the unique demands of our global clientele.